How is diesel made from waste plastic?

Waste Oil Distillation Plant / Date:May 19, 2022

As we know, plastic is a kind of petroleum product made up of polymers; in other words, plastic is made from crude oil extracted from under the ground. Therefore, by recycling waste plastic, we can also get products like diesel. Right now, waste plastic to diesel recycling machine is a hot choice for most investors to get diesel from waste plastic.

The waste plastics to diesel recycling machine mainly uses the principle of pyrolysis to decompose the waste plastic polymers into smaller carbon chains, namely fuel oil. And the fuel oil is then further refined into diesel. The waste plastics to diesel recycling machine designed and manufactured by Doing Company has the latest high temperature pyrolysis and refining technology, which can ensure that the waste plastic is fully pyrolyzed, condensed and refined into diesel so as to bring great considerable profits to investors.

Waste plastic to diesel plant

Waste plastic to diesel plant

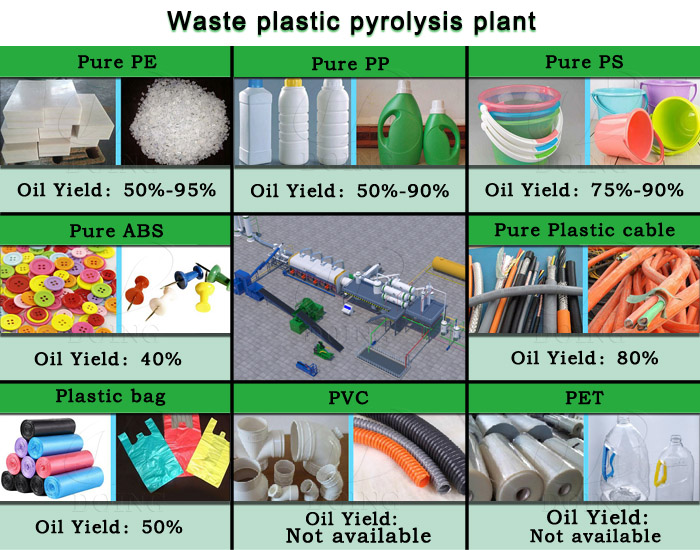

However, plastics is complicated and it has various kinds of types. Can all plastics produce good quality diesel? The answer, of course, is negative.

Firstly, PVC and PET are not suitable to obtain fuel oil through the way of pyrolysis. PVC can release corrosive chlorine under high temperature and produce HCL during pyrolysis reaction, which is not good for pyroysis reactor of waste plastic to diesel recycling machine. PET produces alcohol rather than fuel oil during pyrolysis. So pure PVC and PET are not suitable as the raw material, but mixed plastics are OK. The diesel got from mixed plastics can be used as industrial heating fuel for brick factories, cement factories, steel mills, etc.

PE is a very good kind of plastic to obtain good quality diesel. But PE has problems with paraffin wax. To get good quality diesel from PE plastic, you need to use a special catalyst that can effectively remove the paraffin wax mixed inside the fuel oil.

PP and PS are mostly recommended if you wanna get good quality diesel and use it for transportation vehicles. Since the molecular structure of hydrocarbons of the diesel got from PP and PS are very close to normal diesel. However, PP and PS plastics are not as common as other kinds of plastics in our daily lives, usually their price is relatively higher.

Different plastic with different oil yield

Different plastic with different oil yield

So we can see the diesel quality is different for different kinds of plastics. If you wanna make higher quality diesel from plastics, please feel free to contact Henan Doing Company to get the best solution and customize the best waste plastic to diesel recycling machine at 100% factory price!

Finnaly,purchase and install the plastic to oil pyrolysis plant. During the installation process of the plastic to oil pyrolysis plant, DOING can send engineers to train the workers and carry out the installation and debugging of the equipment. At the same time, DOING will provide after-sales guidance and assistance from a number of overseas engineers.

Two types waste oil distillation machines

Two types waste oil distillation machines

If you are interested in starting the business to convert plastic to oil in Japan, please feel free to contact Henan Doing Company. As a professional waste to oil pyrolysis plant manufacturer, we can customize you the best plastic to oil pyrolysis plant at preferential price and help you to maximize the profits of starting the business of converting plastic to oil in Japan.

Request Information

Send your inquiry for further information